Toe Geometry - Tuning Wheel Alignment

The toe measurement is fundamental to wheel alignment for any road or race car because it changes handling performance and even tyre wear.

- Learn what toe is

- How to tune it to improve performance

- Ways to measure toe

- How to adjust toe

What Is Toe?

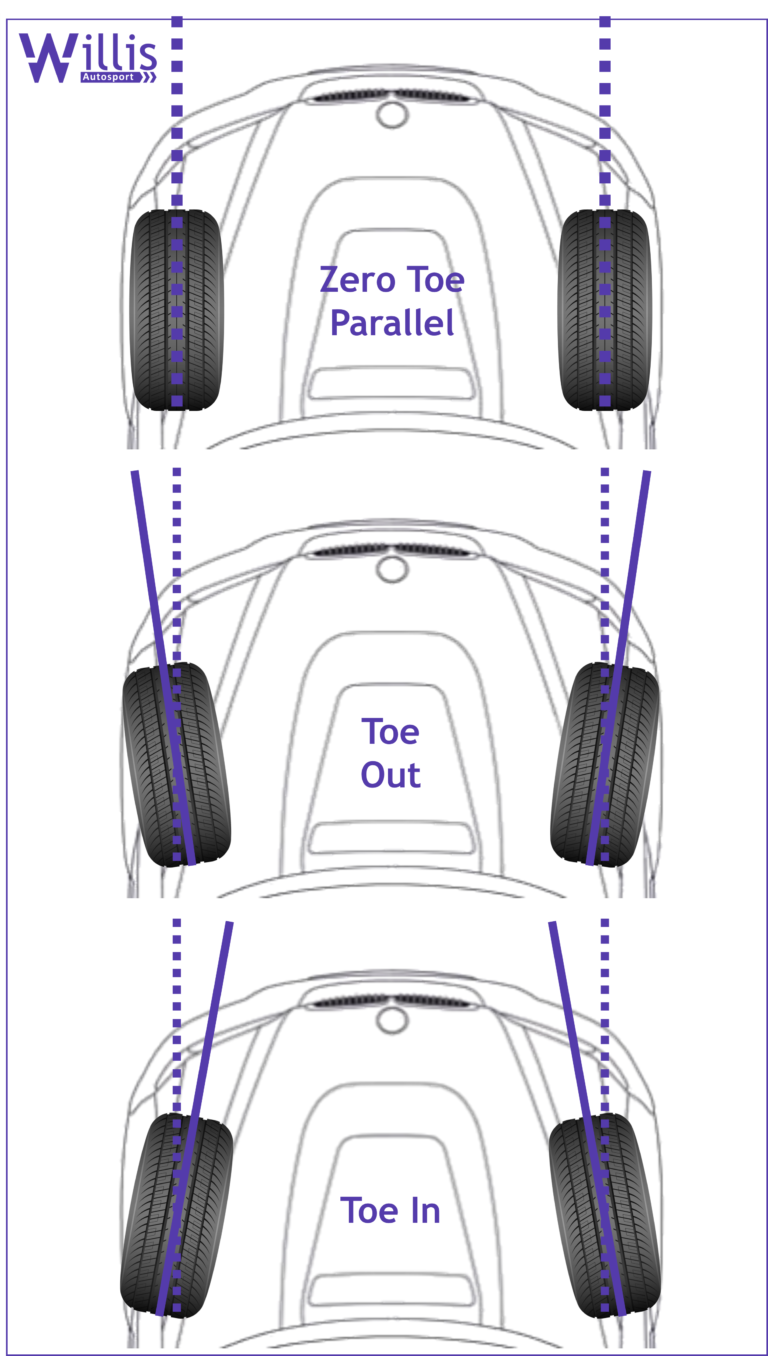

If you imagine you’re looking at the vehicle from the birds-eye view with the front of the car at the top and if the tips of the wheel are pointing in, this is toe-in. If the wheels are parallel, this is zero toe. If the wheels are pointing out, this is toe-out. The toe geometry refers to the symmetrical angle the wheel creates with the longitudinal axis of the vehicle, which is usually measured when the vehicle is static.

Literally, point your toes

An easy way to remember the different types of toe is, when standing, look down at your feet – if your toes are pointing in, it equals toe in. Then, you rotate them to point out: it’s toe-out. If they are not pointed in or out, you are parallel with zero toe. Hence the name toe in, toe out etc.

The quick thinkers may be looking down at their feet and wondering, what happens if both feet ‘wheels” are in different directions? In this situation, your alignment is out; the car won’t drive straight and you need the geometry fixing wheel alignment.

How Toe Affects Performance - Toe Tuning

Toe can be used to enhance chassis setup by

- Making the car agile

- Turning sharply or stables

- Inspiring confidence in high-speed corners

Using the three different toe angles have very different effects depending on whether the wheels are the front axle or rear axle. Also, if the wheels provide the driving momentum, it causes different effects for front-wheel-driven (FWD), rear-wheel drive (RWD) or all-wheel drive (AWD).

The following sections will break down these effects, so you understand the dynamics and what can improve the handling of your vehicle.

Toe-In Front Wheels

Having the front wheel toe-in will make the car feel stable when driving straight as both wheels are pointing ever so slightly towards each other. Imagine you’re looking down on the front wheels, then draw a dotted line between each wheel, then another dotted line in the direction of each wheel is pointing. This creates a triangle with the point of intersect far in the distance in the centre of direction for travel. As other wheels are heading to this point, it makes it stable when driving. As both wheels are heading to a centre point, it requires a larger input from the driver before a direction change.

Toe-in also reduces the Ackermann steering geometry. Both wheels pointing in reduces the angular circumference of the steering by reducing the car’s ability to turn and low-speed corner agility.

The slight anti-Ackermann effect of toe-in can give more grip, reducing excessive tyre slip angle on highspeed cornering, thus improving grip on larger radius corners.

The tyre will also heat up faster because toe-in increases the tyre’s slip angle. Heating the tyre increases adhesion, making the tyre sticky and enhancing grip. As you may have noticed within your own experiences, driving on cold slick tyres are like driving on ice, and only begin working once they are warm, hence the necessity of having a green flag lap in circuit racing.

Slip angle tangent

Now, we need to go on a slight tangent about slip angles, so we all understand what’s going on (but we will be coming back to toe-in).

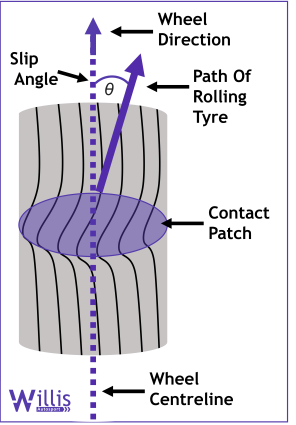

Slip angle is the difference between the direction in which a wheel is pointing and the direction of moment vehicles (see image below).

Do not get the wrong idea about increasing slip angle to generate more grip: having the wheels pointing at a ridiculous 45 degrees won’t help!

There is a window where the tyres’ maximum friction and deformation from slip angle provide peak grip. This is the window we are aiming to work in with the settings. (Learn more about tyres in an article coming soon.)

Back to toe in on the front wheel: increasing heat to aid adhesion to improve grip only works to a point. The consequence of heating the tyre faster though deformation is increased tyre wear, subsequently reducing tyre life from the stresses on the rubber.

Nobody wants a stressed rubber!

The greater the amount of toe-in applied, the greater the reduction in top speed. Excessive toe-in can lead to uneven tyre wear with the outside edge getting worn away fastest.

If the front wheels are driven in such a way for FWD and AWD vehicles, the increased tyre slip angle results in increased grip. As the driven wheel has more grip, acceleration improves.

Running toe-in on RWD will reduce straight-line speed and acceleration as the grip generated by undriven wheels increases drag.

Parallel / Zero-Toe Front Wheels

Top speed can be improved by running zero-toe on the front wheels as this reduces resistance by minimising tyre stress. The minimum tyre stress improves tyre life, making zero-toe, or very close to, which is popular with road cars where tyre life is very important. Endurance racing may also use a front wheel set-up close to zero-toe to maximise tyre life, increasing the distance between pit stops.

With zero-toe, the driver steering inputs are the most neutral, neither enhancing nor reducing high-speed corner stability, or low-speed cornering ability.

Zero front toe on the driven wheels, especially for AWD and FWD, can slightly reduce acceleration as there is a reduction in the tyre slip angle that was generating grip.

Toe-Out Front Wheels

A toe-out set-up on the front wheel can make the vehicle turn-in better on lower-speed corners, improving agility. It does this by aiding the Ackermann geometry needed by the front wheel to turn a corner.

Ackermann Steering Geometry

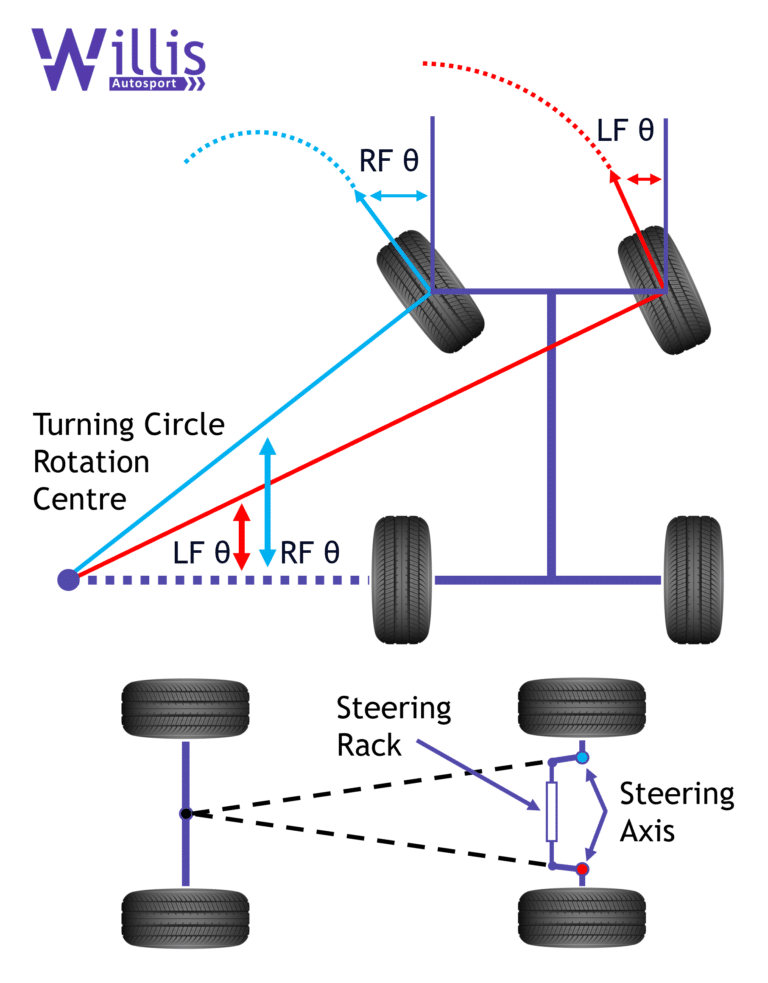

Picture a car turning left in a circle: both front wheels turn when the steering is turned, however, not by the same amount. If you look at the left front (LF) wheel compared to the right front (RF), the LF needs to turn a much tighter circle as it’s on the inside of a corner. The RF is on the outside of the turn, thus it follows a wider corner radius, turning less.

The Ackermann geometry is achieved by drawing a line from the front wheels’ steering axis to the centre of rear axle. Having the steering arm from the hub connect to the steering rack along this line will give the steering system Ackermann.

With the toe-out increasing the Ackermann effect, this helps with steering turn in tight twisty low-speed corners.

Toe-out in high-speed corners can reduce front tyre grip. High-speed corners are long and sweeping, and load the outside tyre much more than the inside. Looking at the tyre performance curve, less slip angle is required at light loads to maximize grip; due to toe-out increasing Ackermann, it scrubs the inside front along the ground in a high slip angle, which is much higher than peak on the later force curve. The drag resistance from the inside front will also slow the car down.

Reverse-Ackermann, or even parallel steering, is sometimes used on race cars, but is calculated to work with a specific type in a specific championship. Zero-Ackermann parallel is also popular in drifting as having both front tyres point the same way helps maintain a predictable slide.

Enough Ackermann tangents – back to toe-tuning!

In much, the same way as before the tyre heats up fast as toe-out increases tyre slip angle. The improved adhesion from hot tyres makes them sticky, enhancing grip.

Heating the tyre faster reduces tyre life from the stresses on the rubber.

The greater the amount of toe-out applied the greater the reduction in top speed. A Lot of toe-out can lead to uneven tyre wear with the inside edge getting worn away fastest. This is not to be confused with inside tyre wear created by negative camber. To tell this these types of tyre wear apart run your hand down the warn edge then back. If it feels smooth one way then rough the other its from the excicive toe scrubbing the tyre along the ground.

As front wheels are driven on FWD and AWD vehicles the increased type slip angle results in increased grip. As the driven wheel has more grip it improves acceleration.

Toe out on the front wheels of an RWD will reduce straight-line speed and acceleration as the grip generated by undriven front wheels causes drag. Wheel can be pulled to 0 toe by drive around steering links

Toe-In Rear Wheels

Toe-in on the rear axle will make the vehicle more stable during high-speed corners. During the corner, weight transfers to the outside tyre. As toe-in points the loaded tyre in the direction you’re turning, it works against the steering reducing rotation and oversteer.

This is excellent at reducing the snappiness of a short wheelbase, giving the diver the feel of a longer wheelbase.

The negative of a stable rear-end is that the car is less agile and nimble through tight slow-speed corners, requiring greater steering inputs.

The increased slip angle of toe-in increases tyre grip, heating the tyre faster, however, reducing tyre life.

On an FWD, having more grip at the rear creates more drag; this resistance reduces acceleration and top speed. As FWD are harder to get heat into the rear tyres, using toe in to help generate heat can aid an inexperienced driver.

Ever been at a race meeting and seen a car lose it and spin out on the green flag lap?

Now you know why: an inexperienced driver running out of talent is attempting to heat their rear tyres.

When the rear wheels are driven in RWD and AWD appreciation, extra grip from increased slip angle aids acceleration, but reduces top speed.

Something to be considered is that increasing rear grip too much will increase understeer, particularly on RWD, because the rear axle is pushing the front straight, resisting the driver’s steering inputs.

Drift cars having a stable, grippy rear can make the car easier to drive and drift better at high speeds. The stability from toe-in makes the rear more predictable, allowing the driver to control the drift on the throttle. The extra grip that the rear allows helps drive the car forward during the drift, reducing risk of spinning out. High-power drift cars are often grip-limited, so with more grip from the toe-in setup, it allows you to put the power down to produce higher-speed drifts with more smoke.

Parallel / Zero Toe Rear wheel

Running zero-toe is neutral, neither enhancing nor reducing stability in high-speed corners or low-speed corners “in principle”. The reduction in slip angle lowers tyre stress having a few direct effects, aiding in maximising tyre life, reducing heat, reducing rear grip, and drag. The reduction of drag increased top speed and fuel range for long-distance races. In reality, cars generally don’t like zero-toe as there is no centring force, so a slight toe-in/toe-out is the best way to gain the principle benefits of zero-toe.

With a zero-toe setup, FWD acceleration can increase as there is less resistive drag from the rear axle to overcome. Meanwhile, with zero-toe, RWD acceleration is reduced with the rear grip lessened. Zero-toe points the wheels straight ahead which can reduce the rear end from wandering when compared to toe-out, however toe-in on the rear is the more stable setup.

Toe-Out Rear Wheels

Running toe-out on the rear axle makes for an “interesting” drive. It increases rotation, making the rear of the car lively. Whilst this can improve performance in tight corners (as it will turn faster and tighter), if the rotation is not controlled properly, it’s prone to become oversteer. As RWD cars can use throttle to control rotation in a predictable, controlled way, the increased rotation with toe-out isn’t always a desirable effect.

To an inexperienced driver, a very lively rear end can result in occasionally spinning out, their heart beating very fast and small, brown stains on their underwear.

During the corners, the weight transfers to the outside wheel. As toe-out points the wheel out, this is how it aids in rotating the vehicle around the corner, beneficial as cars require less steering input to turn.

But doesn’t this mean that the car may feel unstable through high-speed corners?

Yes – this set-up leads to an unstable platform and drivers may be prone to oversteer in the fast, scary corners, leading to some of those brown stain moments that will make you either feel like a hero, or force you to get your chequebook out.

The increase in slip angle results in stress-reducing tyre life, but enhancing adhesion and grip.

On FWD, the rear wheels being undriven means the extra grip from the toe slip-angle results in more drag, reducing acceleration. The greater the angle of toe applied, whether toe-out or toe-in, means all cars will experience a reduction in top speed.

For any drifters in low powered cars, toe out on the rear can help initiate a drift.

How To Measure Toe

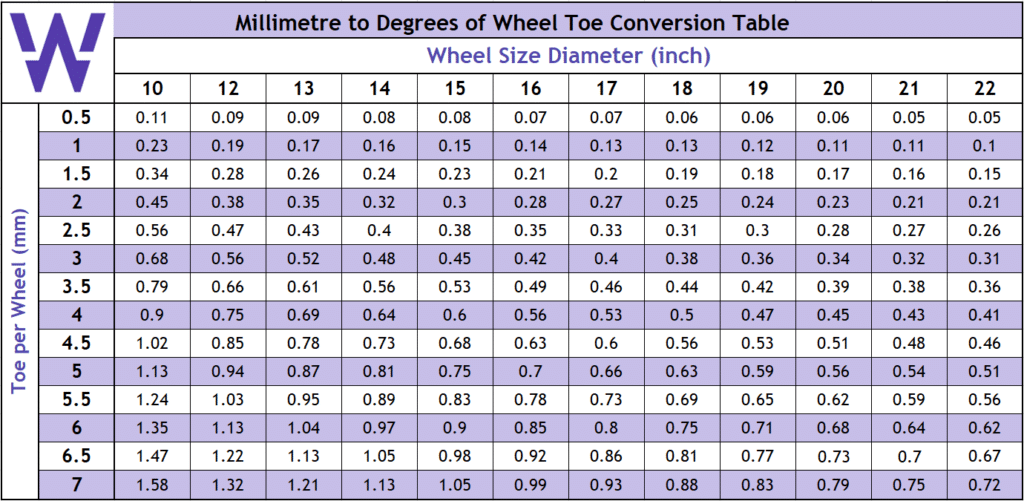

The toe measurement is usually taken from the outside lip of the wheel rim to a parallel axis line to the chassis. The difference in distance between the front and rear edge of the wheel to the axis gives the toe reading in mm. This is most visually clear when you can see the string line alignment method. Other measurement methods have equipment clamps to the wheels to measure the angle of the wheels, providing readouts in degrees, or maybe minutes.

Here to help you is a conversion table to equate toe reading for degree to mm for different wheel sizes.

Improve accuracy

Before any wheel alignment, check for buckled wheels; the buckle in the wheels will provide a false reading causing the alignment to be set wrong.

Another top tip: setting all the tyres to the target pressure increases the consistency of measurement.

String Line Alignment

As old-fashioned and low-tech as the name suggests, string alignment remains the most popular measurement method in the motorsport industry as it’s portable and easy for the race team to set up trackside. It provides an accurate reading for each individual wheel. There is a variety of equipment used for this method, but it all comes down to these key features.

- Two strings are set to run parallel along the outside of the chassis.

- The height of the string is set to the middle of the wheels.

- Then, measurements are taken from the front and rear lip of each wheel rim to the string.

If the larger number is at the rear lip, you have to toe-out; if the larger number is at the front lip, you have toe-in. The difference between the numbers is the amount of toe given in mm.

Higher-level motorsport use another piece of equipment with a string kit: set-up wheel. These are usually machined blocks that bolt to the hubs instead of the wheels, giving two advantages:

- It improves accuracy by removing potential buckled wheels to give false readings.

- It allows mechanics to have easy access to the hubs and suspensions for any adjustments to the car whilst at ride height.

Toe Plates

Another simple method to measure toe is to use toe plates. Here:

- A straight plate is placed at the outside of each wheel and a measurement is then taken between the back edge of the left plate to the back of the right.

- Then, do the same between the front of the left then right plate.

- The difference between these numbers gives the total axle toe measure in mm.

- Opposite to the string alignment method, the larger number at the rear wheel edge is toe-in, whilst greater number at the front is toe-out.

Toe plates are easy and simple to use, but have a large flaw. They can only provide measurements across the axle, not individual wheels. If both wheels are not symmetrical, it could cause the car to pull to one side.

Non-Symmetrical Example: The front axle might read 4mm toe-out total on the plates, however, the wheels might be 2mm toe-in and the other 6mm toe-out, giving a false reading of 4mm out. This would cause the vehicle to pull to the side with 6mm out. Knowing if both wheels are running true means you will be able to adjust the wheels to 2mm toe out each, 4mm out total across the axle, giving a symmetrical reading and straight driver car.

Laser Wheel Alignment

These systems use equipment that hangs on the outside of the wheel rim. By point lasers across the axle to the other opposite side (left to right), it can give total axle toe readings. By pointing lasers to the equipment mounted on wheels on the same side but opposite axle (front to back), it will tell the user if the well is running true/symmetrical.

4 Wheel Alignment Machine

Most road car garages will use a large 4-wheel alignment machine to adjust wheel alignment. These machines are often fitted to four post ramps. They attach equipment to each wheel. Depending on the brand, a mixture of laser, mirror and sensor are used to check each wheel’s geometry which provides a reading in degrees/minutes to a display screen.

How To Adjust Toe

There are a variety of ways to adjust toe geometry, depending on suspension setup and vehicle style. A specially built single-seater racer will be different from a fast road car.

Common methods covered

- Track rod

- Eccentric washers

- Shims

- Adjustable arms

Track Rod

The most common way front-toe is adjusted actually is the same for road cars as purpose-built race cars. It uses the track rods connected to the steering rack (sometimes referred to as tie rods, but I will continue to refer to them as track rods as they are used to adjust the cars tracking).

The track rods consist of two parts:

- Track rod end: connected to the hub with a ball joint, a female threaded hole that connects to part two.

- Inner track rod: this is a partly threads bar that contests the track rod end to steering racks with bearing.

Having bearings joints at both ends allows for suspension movement.

To adjust the toe, it’s simply an act of threading the inner track rod bar in or out of the female threaded track rod end, making the total track rod length longer or shorter. As it is connected to the hub on one side, the lengthening or shortening will toe the wheels in or out.

Eccentric Washers

Popular on-road cars, eccentric washer system utilises a bolt and washers with hole offset to one side. As the bolt and washers rotate, the offset hole moves the position of the bolt in or out. Applied to the toe arm, suspensions pickup points; this movement can be used to adjust the wheel’s toe. However, adjustment is limited because of size and, as the washers are round, once it’s adjusted to its max point it will decrease in adjustment.

Shims

Using toe shims are a very common solid axle vehicle. For some odd reason, for FWD cars with solid rear axle, people tend to say it can’t be adjusted; this is false, and you will now learn how it works and to do it.

A solid shim or plate is used to space the hub from the axle at the required angle. The shim plates are precision machined with a tapered face; when the hub is solid bolted to the axle, the sim place sits in-between spacing the hub to the toe angle required.

Once set, it is very unlikely for the geometry to be unaligned, even with some apex curb strikes on track.

If it does move out of alignment, this usually means the axle is bent. If the axle is bent, this usually means the car has hit something hard and solid like a wall, and then I would suspect you have more urgent priorities…

The use of shims is not limited to solid axles. Some purpose build race cars will use these shims with double wishbones suspensions. In this application, the hub is adjustable. The shims are used between the arms mounting points, giving full adjustability without affecting suspension system geometry e.g. bump-steer.

Adjustable Arms.

An excellent replacement for Original Equipment Manufacturer (OEM), suspension arms/toe links are adjustable arms. As they provide a much larger range of adjustment to than eccentric washers, these adjustable arms replace the stock suspension link. Similarly to the track rod system, they are made with a threads section that can be screwed out to lengthen, or in to shorten, the arms-length, thus changing the wheel alignment.

These are an excellent upgrade if you’re converting road cars to push the limits on the track. Many motorsports vehicles like TCR cars, or factory-built race cars, use adjustable arms as they provide excellent adjustability.

Road Car Adjustment Tip

As road cars are used in all weather conditions, adjusters are prone to rust and therefore seizing. Applying some penetrating fluid, serious heat from a torch to the nut and some lubricants to a bushing will reduce hours of stress and swearing.

There is another way to release a nut and stress with lube and penetration, but this definitely isn’t the website for that!

Tyre Wear

Fundamentally, the greater the toe angle, the greater the increase to the tyre-wear.

Toe-In – Results in more wear to the outside of the tyre. As the vehicle drives straight, the moment is directly forward but the wheels are slightly pointed in, which causes wear to the outside leading edge of the tyre. The inverse is true for toe out.

Toe-Out – Will cause increased wear to the inside edge of the tyre. When tuning your wheel alignment set-up, be mindful that negative camber also increases wear to the inside edge (the compounding effect from both of these is not to be overlooked if tyre life is a performance factor).

Something to note about tyre wear is that it can be caused by a few other things, one of those being camber angle. There are different types of camber that will wear the tyre differently. Click here to learn more about camber angle wheel alignment geometry.

Camber is a great tool for tuning car setup to maximize grip.

Next Step...

I’m grateful for you taking the time to read all of this. Hopefully, this has given you a new insight into a way to tune your car to drive better.

Have you found reading this useful? For more information and tuning tips, I would recommend checking out our other free resources and articles.